Multilayer Rigid Flex PCB: Cost-Effective PCB Prototyping Services at FastTurnPCB

In the rapidly evolving electronics industry, efficient prototyping is essential for bringing innovative products to market quickly and economically. Developing a new electronic device requires testing multiple design iterations, validating functionality, and ensuring manufacturability—all within tight timelines and budgets. FastTurn PCB, a leading provider of multilayer rigid flex PCB solutions, offers cost-effective PCB prototyping services designed to help manufacturers accelerate product development without compromising quality.

By leveraging advanced manufacturing technology, rapid turnaround, and turnkey services, FastTurnPCB ensures that electronics manufacturers can prototype efficiently, iterate faster, and move seamlessly into full-scale production.

The Importance of Cost-Effective PCB Prototyping

Prototyping is a crucial step in electronics development for several reasons:

- Design Validation: Ensures the layout, connections, and functionality are correct

- Risk Reduction: Identifies potential issues before full-scale production

- Cost Management: Avoids expensive mistakes in high-volume manufacturing

- Time Efficiency: Accelerates product development cycles

For companies developing complex devices, particularly with multilayer or rigid-flex designs, prototyping must be both precise and affordable. FastTurnPCB specializes in multilayer rigid flex pcb prototyping to address these critical needs.

Advantages of Multilayer Rigid Flex PCBs in Prototyping

Multilayer rigid flex PCBs combine rigid layers with flexible circuits, offering unique benefits during prototyping:

- Compact and Lightweight: Flexible layers allow integration into small, space-constrained devices

- Durable Construction: Resistant to bending, vibration, and mechanical stress

- Complex Circuit Support: Allows high-density interconnects for sophisticated electronics

- Reliable Performance: Reduces connection failures and ensures prototype consistency

These advantages make multilayer rigid flex PCBs ideal for developing next-generation electronics, from wearables to automotive modules and medical devices.

FastTurnPCB’s Cost-Effective Prototyping Solutions

FastTurnPCB provides comprehensive services designed to streamline prototyping while keeping costs manageable:

1. Rapid Design Evaluation

FastTurnPCB collaborates with clients to evaluate PCB designs and optimize for manufacturability:

- Design-for-manufacturability (DFM) reviews

- Layer stackup and trace routing optimization

- Material selection guidance for rigid-flex and multilayer designs

- Thermal management and signal integrity analysis

These evaluations reduce the risk of errors, saving both time and money during prototyping.

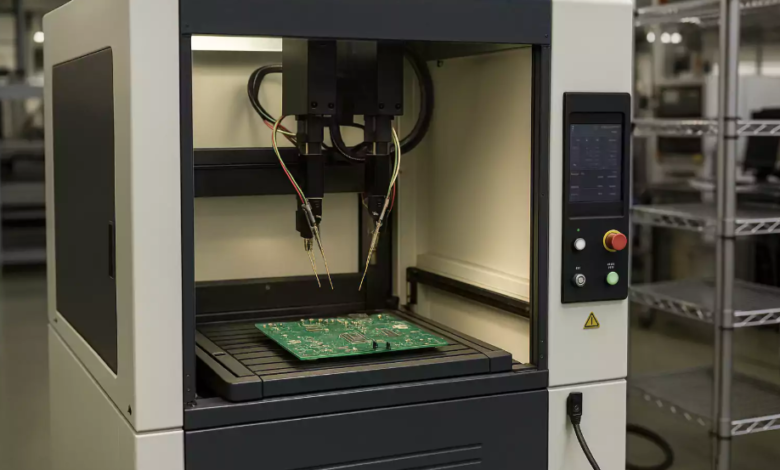

2. Efficient Fabrication

Using advanced fabrication equipment and techniques, FastTurnPCB produces high-quality prototypes efficiently:

- Multilayer PCB fabrication, including rigid, flexible, and rigid-flex designs

- Fine-line etching for dense circuit patterns

- High-precision lamination and microvia integration

- Controlled material selection to ensure reliability

By streamlining fabrication, FastTurnPCB helps manufacturers produce cost-effective prototypes without sacrificing quality.

3. Precision Assembly and Testing

FastTurnPCB ensures that each prototype is fully functional and ready for evaluation:

- Surface Mount Technology (SMT) for fine-pitch component placement

- Ball Grid Array (BGA) assembly with X-ray inspection

- Through-hole and mixed-technology assembly

- Electrical and functional testing to verify performance

This attention to detail ensures prototypes accurately represent final production boards, reducing redesign cycles.

See also: Exploring the Advancements and Applications of Small OLED Technology

Turnkey Services for Prototype Development

FastTurnPCB offers end-to-end turnkey services that simplify the prototyping process:

- Engineering support and DFM consultation

- Component sourcing and inventory management

- Fabrication, assembly, and functional testing

- Packaging and logistics for worldwide delivery

By providing turnkey solutions, FastTurnPCB enables manufacturers to focus on design innovation while reducing overhead and complexity during prototyping.

Applications Across Industries

FastTurnPCB’s cost-effective prototyping services support multiple industries, ensuring rapid development of high-performance electronics:

- Automotive Electronics: Infotainment systems, EV modules, and driver-assistance components

- Medical Devices: Wearable monitors, diagnostic equipment, and imaging systems

- Consumer Electronics: Smartphones, tablets, IoT devices, and smart home technology

- Industrial Electronics: Robotics, control modules, and factory automation

- Telecommunications: Networking and communication hardware

By combining affordability with quality, FastTurnPCB allows manufacturers to prototype innovative designs across these sectors efficiently.

Benefits of Choosing FastTurnPCB for Prototyping

- Expertise in multilayer rigid flex PCB fabrication and assembly

- Cost-effective solutions for rapid prototyping

- Advanced fabrication and assembly technology

- Turnkey services from design to delivery

- Rigorous quality control and functional testing

- Collaboration with engineering teams for optimized designs

- Flexible prototyping options to match budget and timeline

These benefits make FastTurnPCB an ideal partner for manufacturers seeking affordable, high-quality PCB prototypes.

Scaling from Prototype to Production

FastTurnPCB helps clients transition seamlessly from prototyping to full-scale production:

- Small-volume prototypes for design validation

- Medium- and high-volume production for market launch

- Scalable assembly processes to maintain quality at every stage

- Support for rigid-flex and multilayer PCB designs throughout production

This approach minimizes production delays, reduces errors, and ensures that the final product meets both quality and performance standards.

Conclusion

Effective prototyping is essential for electronics manufacturers who want to bring innovative products to market quickly and economically. FastTurn PCB, a leading provider of multilayer rigid flex PCB solutions, offers cost-effective prototyping services that combine advanced fabrication, precision assembly, and turnkey support.

By leveraging FastTurnPCB’s expertise, manufacturers can produce reliable prototypes, validate designs, and scale efficiently to full production while minimizing costs and risks.

For manufacturers looking for high-quality, cost-effective PCB prototyping services, visit FastTurn PCB to explore their comprehensive solutions and capabilities.