Enhancing Operational Efficiency with Advanced Filtration Solutions

Understanding the Role of Oil in Industrial Machinery

Industrial machinery relies heavily on oil for lubrication, cooling, and hydraulic functions. Over time, oil can become contaminated with water, dust, and metal particles, which can compromise machinery performance. Contaminated oil can lead to increased friction, higher maintenance costs, and unexpected equipment failures.

Maintaining oil quality is essential to prolong machinery life, reduce downtime, and optimize operational efficiency. Advanced industrial oil purification equipment provides a reliable method to keep oils clean and maintain peak equipment performance.

Benefits of Industrial Oil Purification Equipment

Using industrial oil purification equipment offers several significant benefits for industries:

- Prolonged equipment lifespan: Removing contaminants prevents excessive wear and tear on mechanical components.

- Improved operational reliability: Clean oil reduces the chances of equipment malfunction, ensuring smoother production processes.

- Cost savings: Less frequent oil changes and reduced repair expenses result in lower operational costs.

- Environmental sustainability: Purifying and reusing oil minimizes waste and promotes eco-friendly practices.

Industries that invest in high-quality purification equipment gain both operational efficiency and economic advantages, making it an essential aspect of modern industrial maintenance.

Key Features of Modern Industrial Oil Purification Equipment

Modern purification systems are designed to maximize efficiency and reliability. Important features include:

- Multi-stage filtration: Combining mechanical, chemical, and centrifugal methods to remove different types of contaminants.

- Automated monitoring: Real-time sensors track oil quality and allow proactive maintenance.

- Energy-efficient operation: Systems are optimized to reduce power consumption while maintaining high performance.

- Scalability and adaptability: Equipment can be configured for small workshops or large industrial plants depending on operational requirements.

These features ensure that industrial oil purification equipment not only improves oil quality but also protects machinery from premature wear and operational inefficiencies.

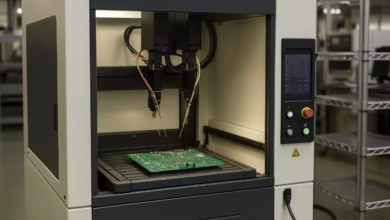

Types of Industrial Oil Purification Equipment

Different industries have varying requirements, which dictate the type of purification equipment needed:

- Centrifugal purifiers: Use centrifugal force to separate water and solids from oil, suitable for high-volume operations.

- Vacuum dehydration units: Remove moisture and dissolved gases, ideal for turbine oils and hydraulic systems.

- Filter-based purifiers: Mechanical filters capture solid impurities, maintaining oil clarity for diverse industrial machinery.

Choosing the appropriate system depends on oil type, contamination levels, and the scale of operations.

See also: Streamlining Checkout Processes with Modern Scanning Technology

Advantages Beyond Machinery Protection

Industrial oil purification equipment provides benefits beyond extending machinery life:

- Operational efficiency: Cleaner oil reduces energy loss and improves machine performance.

- Safety: Purified oil reduces the risk of overheating, corrosion, and equipment failure, ensuring a safer working environment.

- Environmental responsibility: Reusing oil reduces waste and supports sustainable industrial practices.

- Consistent product quality: Maintaining clean oil ensures machinery performs optimally, enhancing the quality of industrial output.

These advantages demonstrate why investment in industrial oil purification equipment is critical for both operational and environmental considerations.

Maintenance and Best Practices

Proper maintenance and industrial oil purification equipment equipment are key to maximizing performance:

- Routine inspections: Regularly check filters, gauges, and oil quality to detect contamination early.

- Timely replacement of consumables: Ensure filters and other components are replaced as needed to maintain efficiency.

- Staff training: Proper training helps operators understand system functions and identify early signs of oil contamination.

- Correct integration: Proper installation within industrial systems ensures seamless operation and reduces downtime.

Following these practices ensures that industrial oil purification equipment consistently delivers optimal performance.

Economic and Operational Implications

Investing in industrial oil purification equipment can result in significant economic advantages. Cleaner oil extends equipment life, reduces maintenance frequency, and prevents unexpected downtime, leading to substantial cost savings.

From an operational standpoint, high-quality oil improves machine efficiency, reduces energy consumption, and maintains production consistency. Additionally, the reuse of oil supports compliance with environmental regulations and promotes sustainable industrial practices.

Emerging Trends in Oil Purification Technology

Advancements in industrial oil purification are making systems more efficient, intelligent, and environmentally friendly:

- IoT-enabled purification systems: Allow remote monitoring, predictive maintenance, and real-time analytics for enhanced control.

- Eco-friendly filtration materials: Innovative filters reduce environmental impact while maintaining high purification standards.

- Compact and modular designs: Systems are easier to install, scale, and adapt to various industrial environments.

- Multi-stage purification methods: Combining centrifugal, vacuum, and filter-based processes achieves near-complete removal of contaminants.

These trends demonstrate that industrial oil purification equipment is evolving to meet the growing needs of modern industry, balancing efficiency, sustainability, and reliability.

Choosing the Right Industrial Oil Purification Equipment

Selecting the right equipment is critical to achieving operational efficiency and long-term benefits:

- Operational needs: Assess the type and volume of oil, level of contamination, and equipment specifications.

- Reliability and support: Partner with manufacturers who provide robust systems and comprehensive after-sales support.

- Cost-effectiveness: Systems should balance purification performance, energy consumption, and maintenance costs.

- Compliance with safety standards: Ensure equipment meets industrial safety and environmental regulations.

Partnering with a trusted provider ensures long-term reliability, consistent performance, and operational efficiency.

Conclusion

Industrial oil purification equipment is a vital component of modern industrial operations. By maintaining oil quality, these systems improve machinery performance, reduce maintenance costs, and support sustainable practices.

Advanced systems featuring multi-stage filtration, real-time monitoring, and energy-efficient designs provide tangible operational benefits. Industries investing in reliable industrial oil purification equipment gain enhanced operational efficiency, extended machinery life, and long-term economic and environmental advantages.

Adopting these systems is not merely a maintenance decision but a strategic move to optimize industrial performance, productivity, and sustainability.