How Steel Mandrel Pigs Support Reliable Pipeline Maintenance

A Brief Look at Pigging in Pipeline Maintenance

Pipeline networks are the backbone of modern energy supply but face continual threats from debris, friction, and internal corrosion. From the earliest days of energy transportation, operators recognized that blockages and buildup within pipelines could slow energy flow or halt operations altogether. This realization marked the origin of pigging—a process that has since evolved into a sophisticated system of regular, automated pipe cleaning. Today, steel mandrel pigs for heavy-duty pipeline maintenance are recognized for their durability and adaptability, making them indispensable in modern infrastructure management.

Today’s energy pipeline networks’ reliability requirements and scale have reshaped industry best practices around pigging. These robust devices have transitioned from simple mechanical scrapers to highly engineered tools that target industrial-scale residues, all while meeting increasingly stringent environmental and safety standards.

Pipeline maintenance goes beyond operational needs—it’s critical for regulatory compliance and long-term asset integrity. Routine pigging is endorsed by leading industry authorities and highlighted in government mandates as essential for maintaining flow assurance and environmental responsibility. According to the U.S. Department of Energy, regular cleaning and maintenance using proven technologies reduces the likelihood of leaks and breakdowns.

As worldwide energy demand grows, the importance of keeping pipelines clear and performing optimally has only increased. Steel mandrel pigs are now foundational to preventative maintenance programs, cutting costs by minimizing unscheduled downtime and unplanned repairs.

How Steel Mandrel Pigs Keep Pipelines Flowing

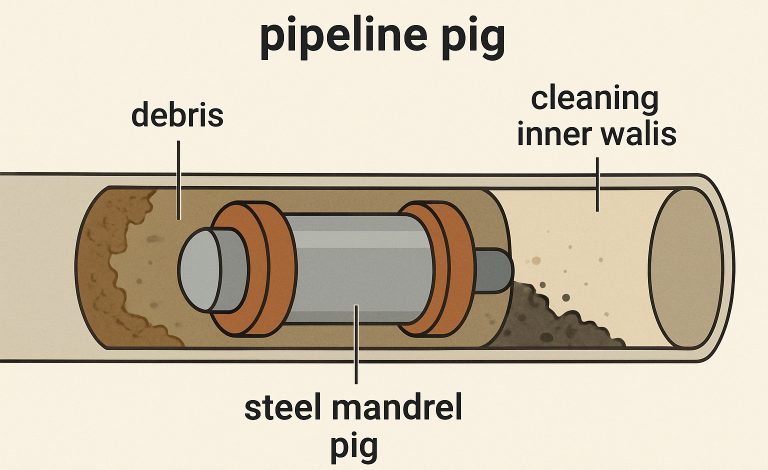

When deployed, steel mandrel pigs travel with the product flow, forcefully removing fouling agents such as wax, sand, and mineral scale. This self-propelled clearing power helps pipelines operate at design capacity and extends the useful life of costly infrastructure. By efficiently managing buildup, these devices play a frontline role in reducing immediate and long-term product throughput risks.

- Eliminate obstructions, ensuring maximum product flow.

- Physically scrape away corrosion and hard scale

- Condition pipelines for safe, accurate internal inspections

- Enable safe separation of different products or batches inside pipes

Data from Pipeline Journal reveals that pipelines left unpigged can experience flow capacity losses up to 20%, underlining the critical importance of pigging to safety and operational efficiency.

See also: WhatsApp Business Chatbot vs Live Agent: Where Should You Invest?

Common Types and Features of Steel Mandrel Pigs

Steel mandrel pigs feature a durable steel core, or “mandrel,” that supports a variety of attachments designed for specific maintenance goals. This design’s adaptability makes it effective for different environments and pipeline contents.

Key Variations Include:

- Cleaning Pigs: Outfitted with brushes, scrapers, or abrasive pads, these pigs tackle hardened incrustations and stubborn internal deposits.

- Batching Pigs: Used to separate various products during transit, preventing cross-contamination within a single pipeline.

- Inspection Pigs: Sometimes combined with sensors to assess wall thickness or detect defects, helping prioritize necessary repairs.

- Specialty Pigs: Tailored for unique pipeline layouts, bends, or severe service applications where standard designs are insufficient.

Selecting the appropriate attachments and pig materials increases effectiveness, safeguards expensive pipeline assets, and maximizes the cost efficiency of each maintenance cycle.

Factors When Choosing the Right Pig

Determining the optimal pig for a maintenance routine begins with thoroughly reviewing pipeline conditions and the operating environment. Important selection factors include:

- Pipeline diameter, length, and operating pressure

- Nature and quantity of internal debris or buildup

- Pipeline material composition and configuration (including bends and welds)

- Expected pigging frequency and long-term maintenance strategy

- Temperature and chemical compatibility with pig components

Maintenance supervisors and pipeline engineers often collaborate to assess these factors and ensure the selected pig can endure operational stresses without causing internal pipe damage.

Best Practices for Pig Maintenance and Operation

Sustainable pipeline operations depend on regular pig maintenance and proper pig selection. Operators should:

- Clean pigs promptly after each run to prevent accumulated debris from hardening or causing corrosion on the pig itself

- Thoroughly inspect the mandrel and attachments for clear signs of wear, fatigue, or structural compromise

- Replace worn brushes, scrapers, and discs to preserve cleaning effectiveness and pipeline safety

- Maintain detailed usage logs and set up routine inspection schedules

- Store pigs in dry, covered environments protected from UV exposure and weather damage

Consistent attention to pig maintenance extends the pig’s service life and ensures a higher level of operational safety and cost management.

Safety and Environmental Considerations

The loading, launching, and receiving of steel mandrel pigs can be hazardous without proper training and equipment. Personnel should be fully briefed on all procedures, adhere to industry safety guidelines, and wear appropriate personal protective gear. Monitoring the pigging process remotely is vital to mitigate exposure to potential hazards.

Environmental stewardship is equally essential. All pigged debris and residual product should be collected, documented, and disposed of according to regulatory standards. These steps safeguard worker health and the surrounding ecosystem, supporting compliance with strict environmental rules.

According to Pipeline & Gas Journal, strict adherence to pigging safety processes significantly lowers the risk of incidents and helps prevent environmental violations.

Recent Innovations and Industry Trends

Innovations in pig design, materials, and data collection capabilities are shaping the future of pipeline maintenance. Advances like “smart pigs” now allow operators to gather real-time data on pipe wall integrity and deposits during cleaning runs, further integrating maintenance and inspection schedules. Additionally, there is a measurable industry push toward automating pig launching and retrieval processes, which helps minimize manual handling and enhances consistency and safety.

New, more resilient composite materials for brushes and scrapers also extend pig lifespan and effectiveness. These changes reflect a broader commitment to safer, more dependable, cost-effective energy distribution.

Frequently Asked Questions

What is the most significant risk if steel mandrel pigs are not used?

The absence of pigging can result in the gradual buildup of obstructions, which increases corrosion, lowers flow rates, and may cause expensive unplanned shutdowns.

How often should pigging occur?

Industry experts recommend creating interval schedules based on pipeline age, content, and contamination risks. Most major pipelines are pigged on intervals ranging from weekly to quarterly, depending on operational conditions.

Are steel mandrel pigs reusable?

Yes, provided they are cleaned and inspected consistently after each use. Most models are built for repeated heavy-duty service cycles.

Ensuring pipeline reliability requires consistent maintenance, and specialized tools are crucial. By enhancing cleaning efficiency and detecting potential concerns early, these solutions extend the lifespan of critical infrastructure. Proper use supports safer operations, reduces costly disruptions, and promotes long-term system performance.