Importance of PCB Cleaning Machines in Modern Electronics

Introduction to PCB Cleaning Machines

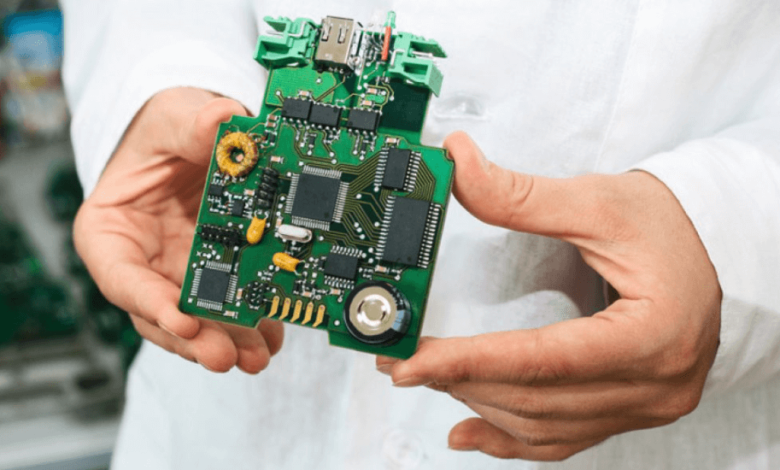

Printed circuit boards (PCBs) form the backbone of virtually all electronic devices. Ensuring that these boards are free of contaminants is critical for reliable performance. PCB cleaning machines are specialized equipment designed to remove flux residues, dust, oils, and other impurities from circuit boards. Proper cleaning not only improves electrical conductivity but also extends the lifespan of electronic assemblies.

Why PCB Cleaning Machines Are Essential

Ensuring Electrical Performance

Contaminants on PCBs can cause short circuits, corrosion, or signal interference. PCB cleaning machines use advanced cleaning techniques to remove residues that can compromise performance. By ensuring clean surfaces, these machines help maintain signal integrity and overall device reliability.

Supporting Automated Assembly Lines

Modern electronics manufacturing relies heavily on automation. PCB cleaning machines are integrated into production lines to maintain consistent quality without slowing down assembly processes. They work efficiently alongside soldering, inspection, and testing equipment.

Enhancing Product Longevity

Residues left on circuit boards can lead to premature failure. By thoroughly cleaning PCBs, manufacturers can prevent corrosion, solder bridging, and other issues that reduce product life. This is particularly important in critical sectors such as medical, aerospace, and automotive electronics.

Types of PCB Cleaning Machines

Inline Cleaning Machines

Inline cleaning machines are integrated directly into production lines. They clean boards continuously as they move through the assembly process, offering high throughput and minimal manual intervention. These machines often employ ultrasonic cleaning, spray-in-air, or foam-based cleaning technologies.

Batch Cleaning Machines

Batch cleaning machines are suitable for smaller production volumes or specialized boards. They clean multiple boards at once in a single chamber, making them ideal for prototype or custom PCB manufacturing. Batch machines offer flexibility and thorough cleaning, though they may have slower throughput compared to inline systems.

Ultrasonic PCB Cl#eaning Machines

Ultrasonic machines use high-frequency sound waves to generate microscopic bubbles in cleaning solutions. These bubbles implode pcb cleaning machine on the PCB surface, effectively removing residues even in hard-to-reach areas. This method is highly effective for delicate or densely populated boards.

Spray-in-Air and Foam Cleaning Systems

Spray-in-air and foam cleaning machines apply cleaning solutions directly onto the PCB surface in a controlled manner. These methods reduce liquid usage while maintaining thorough cleaning, making them environmentally friendly and cost-effective for certain production lines.

See also: Exploring the Role of a Custom Smartphone Manufacturer in Modern Tech

Key Features of Modern PCB Cleaning Machines

Precision and Consistency

PCB cleaning machines are designed to clean boards consistently without damaging components. Advanced sensors and automated controls ensure that each board receives the same level of cleaning, reducing variability in production quality.

Compatibility with Various PCB Types

Modern machines are capable of handling single-sided, double-sided, and multi-layer boards. They are also compatible with a variety of component sizes, ensuring versatility across different electronic products.

Environmentally Friendly Operation

Manufacturers increasingly focus on reducing water and chemical consumption. Many PCB cleaning machines use eco-friendly solvents, recycling systems, and energy-efficient designs to minimize environmental impact.

Integration with Inspection Systems

Some cleaning machines incorporate automated optical inspection (AOI) or other verification systems to ensure cleanliness levels meet industry standards. This integration helps detect residual contamination before boards proceed to the next production stage.

Applications Across Industries

Consumer Electronics

From smartphones to gaming consoles, clean PCBs are critical for reliable performance. PCB cleaning machines ensure that consumer devices operate efficiently and meet quality expectations.

Automotive Electronics

Automotive PCBs are exposed to vibrations, temperature variations, and harsh environments. Proper cleaning ensures these boards remain reliable over extended periods, maintaining vehicle safety and functionality.

Medical Devices

Medical electronics demand the highest levels of cleanliness to ensure patient safety. PCB cleaning machines remove residues that could interfere with sensitive circuits in diagnostic equipment, monitoring devices, and implants.

Industrial Electronics

Industrial controllers and automation systems operate in demanding environments. Cleaning machines help protect these PCBs from contaminants that could lead to downtime or equipment failure.

Benefits of Investing in PCB Cleaning Machines

Reduced Failure Rates

By removing residues and contaminants, PCB cleaning machines significantly reduce the risk of electrical failures, rework, or warranty claims. This results in higher product reliability and customer satisfaction.

Improved Manufacturing Efficiency

Automation in cleaning reduces manual labor, speeds up production, and ensures consistency. Companies can maintain higher throughput while reducing operational costs.

Compliance with Industry Standards

Industries such as automotive, aerospace, and medical require strict adherence to cleanliness standards. PCB cleaning machines help manufacturers comply with IPC, ISO, and other regulatory requirements.

Enhanced Product Quality

Clean boards result in better soldering, improved signal integrity, and overall superior product quality. PCB cleaning machines play a direct role in achieving high-quality electronic assemblies.

Challenges and Considerations

Handling Delicate Components

As electronic components become smaller and more delicate, cleaning machines must be capable of thorough cleaning without causing damage. Manufacturers invest in advanced systems to balance cleaning effectiveness with component safety.

Managing Chemical Usage

Selecting appropriate cleaning solutions is critical. Machines must minimize chemical usage to reduce environmental impact while maintaining effective cleaning performance.

Balancing Throughput and Quality

High-speed production must not compromise cleaning quality. Modern PCB cleaning machines are designed to optimize both throughput and precision, addressing this challenge effectively.

Future Trends in PCB Cleaning Technology

Automation and AI Integration

AI and machine learning are increasingly used to monitor cleaning quality, predict maintenance needs, and optimize cleaning parameters for different PCB types. This ensures consistent results with minimal human intervention.

Eco-Friendly Cleaning Solutions

The industry is shifting toward biodegradable solvents, reduced water usage, and energy-efficient designs. PCB cleaning machines will continue to evolve to support sustainable electronics manufacturing practices.

Integration with Smart Manufacturing

PCB cleaning machines are becoming part of smart factories, communicating with other equipment to provide real-time data on production efficiency, cleanliness, and quality control.

Advanced Inspection Capabilities

Future machines will include enhanced inspection features, using AI-powered vision systems to detect even microscopic residues, ensuring boards meet the highest quality standards.

Conclusion

PCB cleaning machines are an indispensable part of modern electronics manufacturing. By ensuring thorough and precise cleaning, these machines enhance reliability, efficiency, and product quality. Investing in advanced PCB cleaning technology helps manufacturers meet industry standards, improve operational efficiency, and maintain competitiveness in a rapidly evolving market. As electronics become more sophisticated, the role of PCB cleaning machines will continue to grow, supporting the production of high-performance, durable, and reliable devices across industries.